High-Grade, Kiln-Dried

Southern Yellow Pine

As a family-owned and operated southern yellow pine lumber producer, we own and operate our sawmill so that you receive consistent quality in our lumber from order to order.

For All of Your Carpentry Needs

We specialize in exporting high quality, clear lumber to Europe, the Middle East, the Caribbean, Asia, Mexico, and many other parts around the world.

Thickness

We offer 4/4″, 5/4″, 1 5/8″, 8/4″, 10/4″, 12/4″, & 16/4″. We also produce Rough Green and KD timbers in 6 x 6, 6 x 8, 6 x 10, & 6 x 12.

Widths

Our widths are 3″, 4″, 5″, 6″, 8″, 10″, & 12″.

Sizes for widths are as follows:

In 4/4″, widths are 3″, 4″, 6″, 8″, 10″, & 12″.

On the 2″, we also have the 3″, 4″, 5″, 6″, 8″, 10″, & 12″.

In all other thicknesses, the widths are 6″, 8″, 10″, & 12″.

Lengths

Our lengths are 3′-20′. In the shorts (3′-6′), we grade out a true sap in 4/4″. In the 8/4″ shorts, we grade out a #1 select which has a high percentage saps, and is very similar to a prime & better grade. Standard lengths on all random length loads are 7′-20′.

Grades

Our grades in 4/4″ are Sap, Merch Select, and #2 Caribbean. In 5/4″-12/4″, the grades are Sap, Prime & better, Merch, and #2 Caribbean. In the 8/4″, we also grade out a #2 Merch that some customers use as a cutting grade. In the Prime & better, we include approximately 20% Saps. In the 16/4″ we offer Prime & better, Merch, and a #2.

We sell our products directly to our customers in all areas to save you time and money. Our products are used in furniture, windows, doors, molding, stairs, cabinets, flooring, and more.

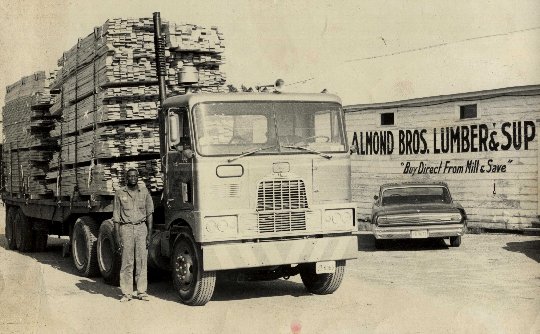

Almond Brothers Lumber Company is a family owned business specializing in the manufacturing of high grade kiln dried southern yellow pine lumber. The lumber is cut from the yellow pine forests of the south central part of the United States. Almond Brothers concentrates on producing lumber with the world export market in mind. Over the last 30 years, Almond Brothers has exported to Spain, The Canary Islands, Germany, Greece, France, Belgium, Denmark, Holland, and Italy, as well as, the Caribbean, Africa, the Middle East and Asia.

Key Personnel

“They are a good family of hard working, humble people. I’ve known them for over forty+ years and enjoyed doing business with them.”

Our History

The Almond family and sawmills date all the way back to the 1860s. Green Almond is earliest ancestor we can trace in the sawmill industry. He was a disabled veteran when he returned home to his farm near Albemarle, North Carolina. Unable to plow because the loss of his arm, he decided to give the sawmill business a try. The first Almond sawmill was on a mountainside near the Pee Dee River in North Carolina.

1800s -1940s

The next generation of Almond lumbermen was Green’s son, Richard Thomas Jackson Almond. He learned the business from Green and followed the South Carolina gold rush to Jefferson, South Carolina before the turn of the century. There, his sawmill supplied lumber to the miners. In 1896, his son, Reno Almond, was born.

In 1909, leaving on a train from McBee, S.C., Richard moved his family to Coushatta, Louisiana and bought several thousand acres of the land. Both he and Reno established separate sawmills. Unfortunately, both mills were lost during the Great Depression.

During World War II, Laurie Almond, one of Reno’s five sons, was able to buy back the 92 acre “home place” and return it to his parents. While serving in the army and air corps, Reno Jr., W. T. Sr., and Cecil Sr. (Tonnie), saved money that would later be used to start the 4th generation’s business.

1940s - 1950s

After the brothers returned from the war, Reno Jr., Tonnie, and Laurie decided to try the lumber industry one more time. They bought a log truck and began producing piling. In 1947, Reno Sr. was instrumental in making a deal on a used portable sawmill. In 1948, they were able to put in a permanent mill. In the early 1950’s, W.T. Sr. joined his brothers and Reno Jr. left to operate his own retail lumber yard in Natchitoches, LA. In 1956, the youngest of the 4th generation, Maxie, joined the business after finishing college.

1950s – 1980s

Just as the business was getting off the ground in 1957, a devastating fire destroyed the planner mill and almost all the finished lumber. Suffering through a great deal of hardship, they rebuilt and overcame adversity.

In the early 1970’s, the 5thgeneration of Almonds began permanent duty with the company after working summers from junior high through college. Laurie’s sons, Ardis and William, W.T. son, Tremmell, and Tonnie’s son, Cecil Jr. make up the 5thgeneration.

In 1980, Cecil Sr. passed away and Laurie and W.T. Sr. retired in 1982. The company was reorganized in 1983 and Maxie left the company.

In the middle to late 1980’s, the company went through a lot of changes toward modernization. Band saws replaced circle saws and gang saws and a modern log merchandising system was built. In 1990, the decision was made to concentrate on the export lumber market in Europe and the Caribbean. In the early 1990’s, further modernization took place as a dry line sorter system was installed as well as a sorter system at the sawmill. In 1994 and 1995, the new office building was built and the ready mix concrete plant was re-located and modernized.

1990s – Present

The 6th generation started working full-time with the company in the 1990s. Winn and Will (Tremmell’s sons) and Vince (Ardis’s son) began work on a permanent basis. In 1997 and 1998, more modernization was done in the form of scanning systems for the carriage and an optimizer system for the edger. In February 1999, the first phase of a new short and narrow mill was started. It is designed to recover 1”x 2” and 1”x 3” lumber from edging strips. It produces lumber from 3 to 7 feet long.

In 2020, the 6th generation became the owners of the company. With over 150 years in the lumber industry, the Almonds always look toward the future but never forget the past. We are proud of our ancestors and the dedication they had to their family and to themselves to provide a way of life for so many generations. As the future unfolds, we will continue to find new ways to preserve the tradition of good family and good business and keep the Almond name in the lumber industry for generations to come.